We use cookies on our website to see how you interact with it. By accepting, you agree to our privacy policy and the use of such cookies.

Varistem helped a coal mine minimise fyrock, noise and airblast, leading to improved retention of blast energy.

A coal mine saw a vast refinement in cast gain in a split blast test, showing Varistem's effectiveness.

Varistem plugs improved fragmentation, loading, haul cycle times, and crusher throughput.

A manganese mine saw huge gains in both lumpy and low grade manganese, from Varistem.

An iron ore mine saw a reduction in waste blasts by using Varistem, saving millions each year.

A metalliferous mine saw the immediate impact of Varistem with improved fragmentation.

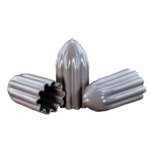

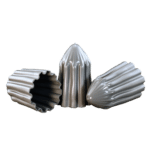

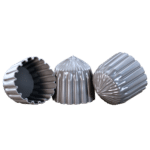

Varistem® stemming plugs are manufactured through a process called dip moulding. This process, in combination with the material type, makes the Varistem® plugs flexible with a high tear strength. When a blast is detonated, an initial pressure shockwave is released that precedes the burning front of the explosion.

Due to Varistem®’s flexibility and high tear strength, once this initial shockwave energy exerts force on the plug, it is forced upwards into the stemming material, and creates a temporary pressure seal in the blasthole. As a result, more of the shockwave energy/explosive gas travels into the microfractures in the surrounding rock, weakening the rockmass.

The initial shockwave is quickly followed by the burning front of the explosion, which destroys the Varistem® stemming plugs. But as a result of the rockmass being weakened by the improved retention of the initial shockwave energy, more of the blast energy travels into the rockmass (even though the Varistem plugs are destroyed in the process).

Good quality stemming practices can have a massive impact on blast outcomes. Simply put – energy follows the path of least resistance, and in blasting this is mostly up and out the hole.

Increasing the resistance in the hole through good stemming practices lets less energy escape (especially the initial shockwave energy), and then results in more energy going into your rock.

The video shows a comparison test we did at a manganese mine on their calcrete material, comparing drill chippings/cuttings to drill chippings/cutting in combination with a stemming device called Varistem.

Leave a comment if you want to see a shot of the fragmentation after!

#blasting #mining #manganese #ironore #miningengineering

Good quality stemming practices can have a massive impact on blast outcomes. Simply put – energy follows the path of least resistance, and in blasting this is mostly up and out the hole.

Increasing the resistance in the hole through good stemming practices lets less energy escape, and more energy going into your rock.

The video shows a comparison test we did at a quarry, comparing normal aggregate stemming to aggregate stemming with a stemming device called Varistem.

Leave a comment and I will share a shot of what the fragmentation looked like.

#blasting #mining #quarrying #energy #miningengineering

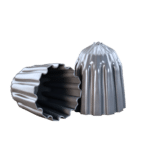

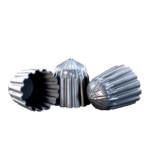

In general we have observed that crest holes are more prone to blowouts than others. In certain scenarios, to combat this, we incorporate a “double-plugging” methodology to improve the energy retention on the crest.

In normal production holes we install one Varistem stemming plug per hole. In the double-plug methodology, we install two with a bit of material between the two plugs (as can be seen in the video).

We apply this same methodology as a remedy on an ad-hoc basis when we encounter challenges like short holes or blocked holes.

#mining #miningengineering #blasting

Managing Director

Eugene Preis | eugene@ergindustrial.com

Operations Director

Reinhardt Steyn | reinhardt@ergindustrial.com

Administrative

Annette Schreiber |annette@ergindustrial.com

+27 60 805 6550

General Enquiries

info@ergindustrial.com | +27 60 805 6550