Scaled Depth of Burial Explained

The article explores the concept of scaled depth of burial (SD) and its significance in mitigating environmental impacts associated with blasting activities in mining and

This article delves into the concept of explosives sensitivity, also known as initiation sensitivity, which is a fundamental property of explosive materials used in the mining and quarrying industry. Initiation sensitivity determines how easily an explosive can be initiated or detonated and plays a pivotal role in ensuring safety and operational efficiency. The article discusses the importance of understanding sensitivity and the various factors influencing it, including chemical composition, physical form, temperature, and confinement. The role of initiating devices, such as blasting caps and detonators, in mining and quarrying operations is highlighted, along with the classification of explosives based on their sensitivity.

The article categorizes explosives into cap-sensitive and booster-sensitive types, emphasizing the role of primary and secondary explosives. It also introduces blasting agents and insensitive high explosives, which cater to specific safety and stability requirements in different applications.

Furthermore, the article touches on velocity of detonation (VoD) and its significance in blast initiation, providing typical VoD values for common blasting components. It underscores the paramount importance of adhering to safety protocols and industry standards when working with explosives in mining and quarrying operations.

Sensitivity, or initiation sensitivity, refers to how easily an explosive can be initiated or detonated. It’s a fundamental property of explosive materials, and in the mining and quarrying industry, it directly influences safety and efficiency. Sensitivity is measured by how an explosive responds to a standard initiating device, such as a blasting cap or detonator. The correlations between the properties of the explosive molecules and materials and their handling sensitivity are thoroughly investigated, as it has been over the last 50 plus years (see Bajpayee & Hay, 1994). The results mostly relied on is the results from drop weight impact tests (Cawkwell et al., 2022).

Any material which cannot be fully detonated with a measurable VoD by either a detonator or another detonation is considered as a nonexplosive. However, this nonexplosive material can be converted into an explosive material by increasing the sensitivity of the material. An example of this is emulsion explosives. Before the gassing process, emulsion is classified as a nonexplosive and dangerous goods due to the low sensitivity. It is only after the emulsion has been gassed that the sensitivity of the mixture increases to the extent where the blasting agent is now booster-sensitive and can be used as an explosive. This is done to ensure the safety of all people involved during the manufacturing, transport and usage of the product and only becomes dangerous when needed during blasting operations. Other safety considerations include accidental initiation or the risk of initiation through electrostatic discharge (see Gabor et al, 2022)

The sensitivity of an explosive assists in the classification of explosive products. In mining and Quarrying there are typically two main classifications namely:

Other explosive classifications typically include primary, secondary and tertiary explosives and will be discussed later in this article.

Blasting caps and detonators play a central role in initiating explosives for mining and quarrying. These small but highly sensitive devices contain primary explosives, such as lead azide or lead styphnate, designed to transmit the initiation signal to the main explosive charge. The cap sensitivity of these initiating devices is closely linked to their effectiveness in igniting the larger explosive charges (Meyer, 2010). The four main stages of rapid decomposition of a condensed explosive are initiation, deflagration, transition from deflagration to detonation and finally, detonation. The rate of transition between these phases and the continuation of hot-spot initiation throughout the explosives column is highly dependent on the initiation phase and the type of initiation device used (Bruckman & Guillet, 1968).

IMAGE: Detonating cord at the hole collar with collar protection

Several factors come into play when determining the sensitivity of an explosive:

The types and proportions of chemicals in an explosive greatly influence its sensitivity. Primary explosives, such as lead azide, are highly sensitive and are used in initiating devices. In contrast, secondary explosives, such as TNT or RDX, are less sensitive and are the primary explosives used in most blasting applications (Cooper, 1996).

The physical state of an explosive also affects its sensitivity. Finely powdered explosives are often more sensitive than crystalline or compacted forms due to their increased surface area (Harlow, 1987).

The sensitivity of an explosive is temperature-dependent. Many explosives become more sensitive at higher temperatures. This is an important consideration, especially in mines and quarries where temperature variations can be significant (Man, 2017).

The degree to which an explosive is confined can alter its sensitivity. Confined explosives are generally more sensitive than unconfined ones. In mining and quarrying, the degree of confinement can vary depending on the specific blasting method and location (Böddeker, 2002).

In mining and quarrying, safety is a top priority, and the choice of explosives is a critical factor. Different types of explosives are used depending on the specific needs of the operation. To provide a rough comparison, primary explosives like lead azide and lead styphnate typically have cap sensitivities ranging from 0.1 to 0.5 millijoules. In contrast, secondary explosives like TNT, RDX, and HMX have cap sensitivities ranging from 1 to 5 millijoules or higher (Hirsch, 1991).

Primary explosives, such as lead azide and lead styphnate, are essential for initiating larger charges. These explosives have the highest cap sensitivity and are used in initiating devices, ensuring that the main explosive charge is activated reliably and safely (Agrawal, 2007).

Secondary explosives, like TNT, RDX, and HMX, are the primary explosive materials used in most mining and quarrying blasting applications. They are less sensitive than primary explosives and are chosen for their stability and safety, making them suitable for larger-scale blasting operations (NRC, 1993).

Blasting agents are mixtures of fuels and oxidizers that are less sensitive than both primary and secondary explosives. Examples include ANFO (ammonium nitrate/fuel oil) and emulsions. Blasting agents require a significant amount of energy to initiate detonation and are often used in mining and construction operations.

Insensitive high explosives (IHEs) are a category of explosives designed to be more stable and less sensitive to initiation compared to traditional explosives. Examples of IHEs include CL-20 (hexanitrohexaazaisowurtzitane) and FOX-7 (1,1-diamino-2,2-dinitroethylene). These explosives are used in applications where safety and stability are critical.

Ammonium nitrate (AN) is a common oxidizer used in explosive mixtures, such as ANFO. While ammonium nitrate itself is not highly sensitive, it can become more sensitive when mixed with fuels or other sensitizing agents.

It’s important to note that cap sensitivity is just one aspect of explosive behaviour. Other factors, such as VOD, brisance (shattering power), density, and stability, also play significant roles in determining an explosive’s suitability for specific applications.

When handling and using explosive materials, it’s crucial to follow proper safety protocols and guidelines to mitigate risks associated with initiation and detonation. Always refer to official safety recommendations, manufacturer specifications, and industry standards when working with explosives.

A key consideration for blast initiators is the desired VoD to be achieved. A bigger booster will yield a higher VoD which means an overdriven explosives column. To ensure the continuation of a certain VoD, multiple boosters can be used throughout the column. Please note that actual VOD values can vary based on specific manufacturers, formulations, and conditions. The VOD is typically measured in meters per second (m/s) or feet per second (ft/s). Typical blast initiator VoD’s are:

In the world of mining and quarrying, where safety is paramount, understanding the sensitivity of explosives is a critical element of successful operations. Sensitivity refers to how easily an explosive can be initiated or detonated and is a fundamental property of explosive materials. It directly impacts the safety of personnel and the overall efficiency of mining and quarrying activities.

Initiation sensitivity has been a subject of thorough investigation for over 50 years, with the results often relying on drop weight impact tests. The ability to initiate an explosive is the fundamental distinction between materials classified as explosives and those deemed nonexplosive. Even materials like emulsion explosives, initially nonexplosive due to low sensitivity, can be converted into explosives by increasing their sensitivity through processes like gassing. This transformation ensures safety during manufacturing, transportation, and storage until the explosives are needed for blasting operations. Safety concerns also encompass accidental initiation and the risk of initiation through electrostatic discharge.

Mining and quarrying operations typically classify explosives into two main categories based on cap sensitivity:

Further classifications of explosives include primary, secondary, and tertiary explosives, which provide more specialized solutions for various applications.

Blasting caps and detonators, equipped with primary explosives like lead azide or lead styphnate, play a central role in initiating explosives for mining and quarrying. The cap sensitivity of these initiating devices is crucial as it directly impacts the effectiveness of igniting larger explosive charges. It determines the rate of transition through initiation, deflagration, transition from deflagration to detonation, and ultimately detonation, which is highly dependent on the type of initiation device used.

Several factors influence the cap sensitivity of explosives, including chemical composition, physical form, temperature, and confinement. Primary explosives like lead azide are highly sensitive, while secondary explosives like TNT or RDX are less sensitive and are the primary explosives used in most blasting applications.

In the mining and quarrying industry, safety remains the highest priority. Various types of explosives are selected based on specific operational requirements. Primary explosives, such as lead azide and lead styphnate, are cap-sensitive and are used to initiate larger charges. Secondary explosives, like TNT, RDX, and HMX, are less sensitive but chosen for their stability and safety in larger-scale blasting operations. Additionally, blasting agents and insensitive high explosives are used for specific applications that prioritize safety and stability.

While sensitivity is a crucial factor in explosive behaviour, other characteristics like velocity of detonation (VoD), brisance, density, and stability, are equally significant in determining the suitability of an explosive for specific applications. When working with explosive materials, it is imperative to adhere to proper safety protocols and guidelines, referring to official safety recommendations, manufacturer specifications, and industry standards.

Agrawal, J. P. (2007). “High Energy Materials: Propellants, Explosives, and Pyrotechnics.” Wiley-VCH.

Bajpayee, T.S.; Hay, J.E. (1994). “Method of Comparing Initiating Strength of Detonators Using Adjustable-Sensitivity Liquid Explosive.” United States Bureau of Mines. Spokane Research Centre, Spokane, WA.

Böddeker, K. (2002). “Initiating Explosives.” In “Explosives” (pp. 1-14). Wiley-VCH.

Bruckman, H.J.; Guillet, J.E. (1968). “Theoretical calculations of hot-spot initiation in explosives.” Canadian Journal of Chemistry, 46, 3221. Department of Chemistry, University of Toronto, Toronto 5, Ontorio.

Cawkwell, M.J.; Davis, J.; Lease, N.; Marrs, F.W.; Burch, A.; Ferreira, S. and Manner, V.W. (2022). “Understanding Explosive Sensitivity with Effective Trigger Linkage Kinetics”. ACS Physical Chemistry, 2, pp448-458.

Committee on Technical Aspects of Critical and Strategic Materials, National Research Council. (1993). “Explosives: Compounds, Mixtures, and Blends.” National Academies Press.

Cooper, P. W. (1996). “Introduction to the Technology of Explosives.” John Wiley & Sons.

Gabor, D.; Paun, F.A.; Tazlauanu, A. (2022). “The danger of initiating explosives by electrostatic discharges.” MATEC Web of Conferences, 373, Universitaria SIMPRO 2022.

Harlow, F. H. (1987). “Detonations.” University of California Press.

Hirsch, P. B. (1991). “Solid State Chemistry of Explosives.” World Scientific.

Man, K. S., Lee, S. H., & Ko, T. M. (2017). “Handbook of Industrial Chemistry and Biotechnology.” Springer.

Meyer, R. (2010). “Explosives.” Springer.

The article explores the concept of scaled depth of burial (SD) and its significance in mitigating environmental impacts associated with blasting activities in mining and

In our business, we are in a unique position where we get to spend time at countless sites, working with drillers and blasters during the planning,

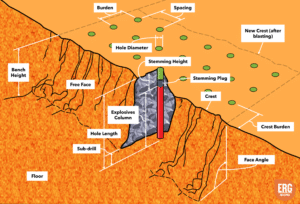

Designing a blast involves the consideration of multiple parameters, and achieving the desired blasting outcome necessitates a thorough understanding of the interplay and interdependence of

Managing Director

Eugene Preis | eugene@ergindustrial.com

Operations Director

Reinhardt Steyn | reinhardt@ergindustrial.com

Administrative

Annette Schreiber |annette@ergindustrial.com

+27 60 805 6550

General Enquiries

info@ergindustrial.com | +27 60 805 6550